Automation is transforming industries. AI robotics systems lead the charge.

In factories, efficiency and precision are crucial. AI robotics systems offer both, revolutionizing how factories operate. These advanced systems handle repetitive tasks, reduce human error, and boost productivity. They seamlessly integrate into existing workflows, making them essential for modern manufacturing.

Whether you’re looking to upgrade your production line or start from scratch, understanding the best AI robotics systems is key. This guide will help you navigate the top options available, ensuring your factory stays competitive in today’s fast-paced market. Dive in to discover how these innovative systems can elevate your factory’s performance and efficiency.

Introduction To Ai Robotics

AI robotics in factories is changing the way we produce goods. Machines with artificial intelligence can perform tasks that were once done by humans. This results in faster and more accurate production. It also reduces human error and improves safety. Factories are now smarter and more efficient. This is thanks to the integration of AI robotics systems.

Emergence Of Ai In Factories

The emergence of AI in factories has been a significant development. Early machines were limited in what they could do. They were programmed to do specific tasks and could not adapt to changes. Now, AI-powered robots can learn and adapt. They can handle complex tasks and make decisions. This makes them invaluable in a factory setting.

AI robots can work 24/7 without breaks. They do not get tired or need rest. This means higher productivity and lower costs for factories. AI robots can also work in dangerous environments where it is not safe for humans. This reduces the risk of accidents and injuries.

Importance Of Automation

Automation is crucial for modern factories. It helps streamline processes and increase efficiency. With automation, repetitive tasks are done by machines. This allows human workers to focus on more complex and creative tasks. Automation also ensures consistency and quality in production.

Here are some key benefits of automation:

- Increased Productivity: Machines can work continuously without breaks.

- Cost Reduction: Automation reduces labor costs and operational expenses.

- Improved Quality: Consistent and precise production reduces defects.

- Enhanced Safety: Robots can handle dangerous tasks, keeping workers safe.

Many factories have already adopted AI robotics systems. These systems are proving to be a game-changer in the manufacturing industry. The future of factories lies in the continued integration of AI and robotics.

Top Ai Robotics Systems

Factories today are moving towards automation. AI robotics systems play a key role in this shift. They help increase efficiency and reduce errors. Here, we explore some of the best AI robotics systems for factories.

Abb Robotics

ABB Robotics is a leader in the robotics industry. They offer a wide range of robots suitable for various applications in factories. Their robots are known for their precision and reliability.

- High-speed assembly

- Material handling

- Welding and painting

ABB’s robots come with advanced AI capabilities. These include machine learning and computer vision. They can adapt to different tasks easily. This makes them ideal for dynamic factory environments.

Here are some key features of ABB Robotics:

| Feature | Description |

|---|---|

| Flexibility | Can handle various tasks |

| Reliability | High uptime and low maintenance |

| Precision | Accurate performance in tasks |

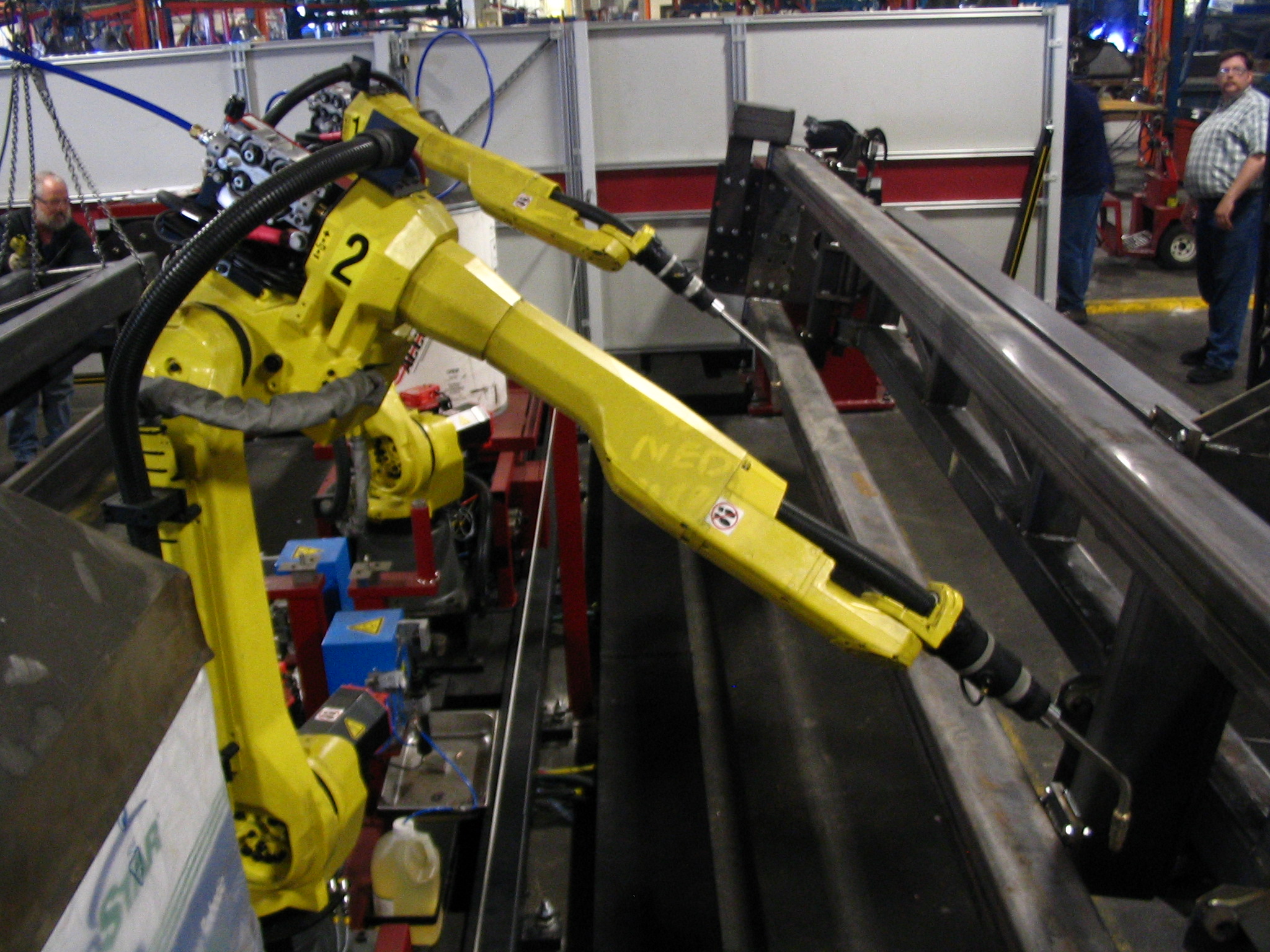

Fanuc Robotics

Fanuc Robotics is another top player in the AI robotics market. They are known for their durable and efficient robots. Their systems are widely used in many industries, including automotive, electronics, and food processing.

Fanuc’s AI robots are equipped with advanced sensors and algorithms. This allows them to perform complex tasks with ease. They are also designed for easy integration into existing factory setups.

Here are some of the advantages of using Fanuc Robotics:

- High precision

- Long lifespan

- Low maintenance costs

Fanuc also offers excellent customer support. This ensures that factories can get the most out of their robotic systems.

Both ABB Robotics and Fanuc Robotics provide top-notch AI solutions for factories. These systems help improve efficiency and productivity. Choosing the right system depends on the specific needs of your factory.

Key Features Of Leading Systems

In today’s fast-paced industrial world, AI robotics systems transform factories. Their advanced features ensure smooth operations and high productivity. Let’s dive into the key features that make these systems stand out.

Precision And Efficiency

Leading AI robotics systems offer unmatched precision. They perform tasks with incredible accuracy. This reduces waste and minimizes errors. Efficiency is another hallmark. These systems optimize workflows. They complete repetitive tasks faster than human workers. This boosts overall production rates.

Safety And Reliability

Safety is a top priority in factories. AI robotics systems come equipped with advanced safety protocols. They detect hazards and prevent accidents. This protects human workers. Reliability is equally important. These systems are built to last. They require minimal maintenance. This ensures continuous operation without frequent downtime.

Credit: www.edge-ai-vision.com

Benefits Of Ai Robotics In Factories

AI robotics systems in factories improve efficiency, enhance precision, and reduce operational costs. These systems streamline production processes, ensuring better quality control and safety.

Implementing AI robotics in factories brings numerous benefits. These systems improve efficiency and accuracy. They also help in reducing errors and waste. Factories using AI robotics often see significant improvements in productivity and cost savings.Cost Savings

AI robotics help factories save money in several ways. They reduce the need for human labor. This cuts down on wages and benefits expenses. Robots also work faster and more efficiently. This reduces the costs associated with production time. Additionally, they minimize errors, leading to less waste and fewer defects. This results in lower costs for materials and rework.Increased Productivity

AI robotics significantly increase productivity in factories. Robots can work around the clock without breaks. This means production continues 24/7. They also perform tasks faster than humans. This speeds up the manufacturing process. AI systems can quickly adapt to new tasks. This flexibility further boosts productivity. Finally, robots ensure consistent quality, which increases overall output. “`Challenges And Solutions

Implementing AI robotics systems in factories presents various challenges and solutions. Factories face unique obstacles during integration and upkeep. Addressing these issues ensures seamless operations and maximizes benefits.

Integration Issues

Many factories struggle with integrating AI robotics systems. Legacy systems often clash with new technology. This mismatch causes delays and inefficiencies. Proper planning mitigates these integration issues.

Comprehensive training for staff is essential. Workers need to understand new systems. This training reduces errors and boosts productivity. Partnering with experienced vendors also helps. They provide valuable insights and support during integration.

Maintenance And Upgrades

AI robotics systems require regular maintenance. Neglect leads to breakdowns and costly downtime. Scheduling routine checks keeps systems running smoothly. Predictive maintenance tools can help. They identify potential issues before they become problems.

Upgrading AI systems is another challenge. Outdated software hampers performance. Keeping systems updated ensures optimal functioning. Allocate resources for continuous improvement. This investment pays off in the long run.

Credit: appinventiv.com

Case Studies Of Successful Implementations

Implementing AI robotics systems in factories has led to significant advancements. Let’s explore real-world examples. These case studies highlight the impact of AI in different industries.

Automotive Industry

In the automotive industry, AI robotics streamline production lines. Toyota, a global leader, uses AI robots for assembling cars. These robots handle complex tasks with precision. This reduces errors and improves efficiency. BMW also benefits from AI robotics. Their robots assist in welding and painting processes. This ensures consistent quality and speeds up production.

Electronics Manufacturing

The electronics manufacturing sector also sees AI robotics success. Samsung, a tech giant, employs AI robots in its factories. These robots assemble smartphones and other devices. They work faster and with great accuracy. This reduces production time and costs. Another example is Foxconn. They use AI robotics to produce electronic components. This enhances their manufacturing capabilities and product consistency.

Future Trends In Ai Robotics

Factories are adopting AI robotics systems to boost efficiency and reduce errors. These advanced robots streamline operations, ensuring consistent quality and faster production times.

The world of AI robotics is evolving at a rapid pace. Factories are seeing significant changes driven by new technologies. Future trends in AI robotics promise to make factories smarter and more efficient. Let’s explore some of these exciting developments.Collaborative Robots

Collaborative robots, also known as cobots, are designed to work alongside human workers. They help with tasks that are repetitive or dangerous. Cobots are safe and easy to program. They can adapt to different tasks quickly. This flexibility makes them valuable in dynamic factory environments. Cobots increase productivity and reduce workplace injuries. They also support workers, making their jobs easier and safer.Advancements In Machine Learning

Machine learning is improving the way robots operate. With advanced algorithms, robots can learn from data. They can predict maintenance needs and optimize workflows. This leads to fewer breakdowns and less downtime. Machine learning also helps robots to adapt to new tasks. They can recognize patterns and make decisions based on past experiences. This continuous learning process makes robots more efficient over time. In conclusion, the future of AI robotics in factories looks promising. Collaborative robots and advancements in machine learning are key trends to watch. These technologies will shape the factories of tomorrow.

Credit: www.britannica.com

Frequently Asked Questions

What Are The Benefits Of Ai Robotics In Factories?

AI robotics improve efficiency, reduce errors, and minimize downtime. They enhance productivity and ensure consistent quality. These systems can operate 24/7 without fatigue.

How Do Ai Robots Enhance Production Quality?

AI robots maintain precision and consistency in repetitive tasks. They detect and correct errors in real-time, ensuring high-quality output.

Are Ai Robotics Systems Cost-effective For Factories?

Yes, AI robotics systems reduce labor costs and increase operational efficiency. They offer long-term savings and quick ROI.

What Industries Use Ai Robotics Systems?

AI robotics are used in automotive, electronics, pharmaceuticals, and food processing. They streamline complex manufacturing processes.

Conclusion

Choosing the right AI robotics system boosts factory efficiency and productivity. These systems streamline processes, reduce errors, and enhance safety. Many options cater to various needs and budgets. Investing in AI robotics can transform factory operations. Stay competitive by embracing advanced technologies.

Research thoroughly and select the best fit for your factory. The future of manufacturing lies in smart robotics.