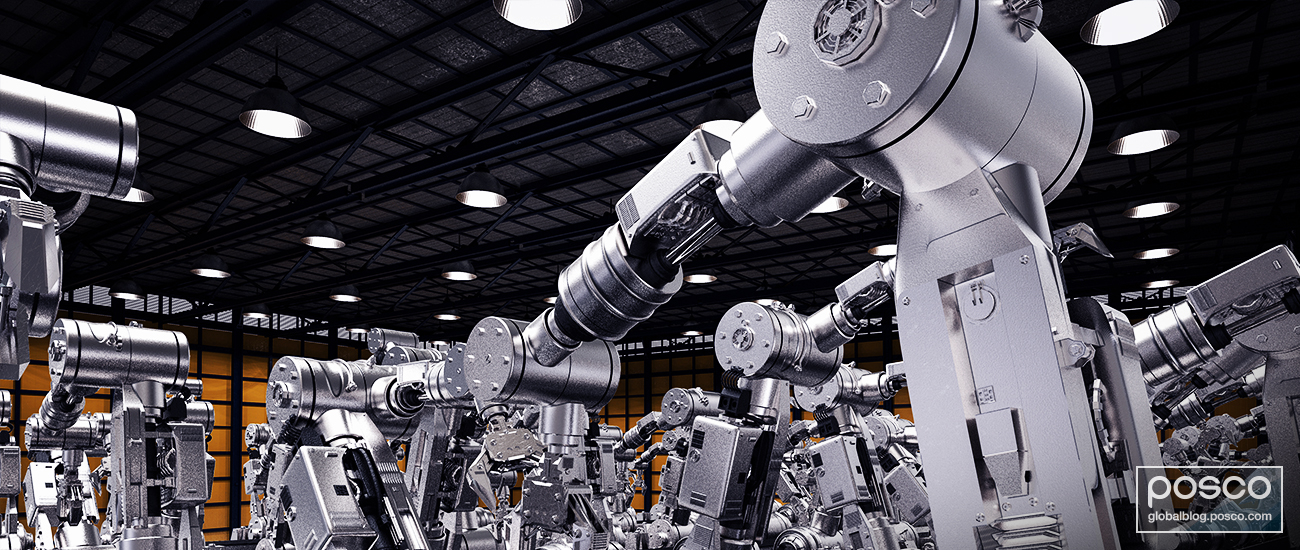

Artificial Intelligence (AI) is transforming the steel industry. It is making processes smarter and more efficient.

In recent years, AI has been a game changer across many sectors, including the steel industry. Traditionally, steel production relied on manual labor and basic automation. But now, with AI, the industry is witnessing significant improvements. AI helps in predicting machine failures, optimizing production, and reducing waste.

It also enhances safety by monitoring hazardous conditions. This shift not only boosts productivity but also cuts costs. As a result, the steel industry is becoming more competitive. Dive in to explore how AI is reshaping the steel industry and what it means for the future.

Credit: www.linkedin.com

Ai-driven Innovations

Artificial Intelligence (AI) is transforming the steel industry. AI-driven innovations are making steel production smarter and more efficient. These innovations are not only enhancing productivity but also improving quality and safety.

Smart Manufacturing

AI is enabling smart manufacturing in the steel industry. Factories use AI to automate and optimize processes. This includes controlling temperatures, monitoring equipment, and managing energy use.

AI systems collect and analyze vast amounts of data. They provide real-time insights and help in making informed decisions. This reduces waste, improves quality, and lowers costs.

| Benefits of Smart Manufacturing |

|---|

| Optimized Production |

| Improved Quality Control |

| Energy Efficiency |

| Cost Reduction |

Predictive Maintenance

AI plays a crucial role in predictive maintenance. It helps in predicting equipment failures before they happen. This is possible through constant monitoring and data analysis.

AI systems can detect unusual patterns and predict maintenance needs. This reduces downtime and prevents costly repairs. Predictive maintenance ensures that machines run smoothly and efficiently.

- Early Detection of Issues

- Reduced Downtime

- Lower Maintenance Costs

- Increased Equipment Lifespan

In summary, AI-driven innovations are reshaping the steel industry. Smart manufacturing and predictive maintenance are key areas where AI is making a significant impact. The result is a more efficient, cost-effective, and safer steel production environment.

Credit: newsroom.posco.com

Enhanced Quality Control

Enhanced Quality Control in the steel industry has seen significant improvements with AI integration. AI technologies now play a crucial role in maintaining and enhancing the quality of steel products. These advancements ensure products meet stringent industry standards.

Real-time Monitoring

Real-time monitoring allows for constant observation of the production process. AI systems analyze data from various sensors in real-time. They detect any anomalies or variations immediately. This helps in maintaining the desired quality of the steel.

Real-time monitoring reduces the need for manual inspections. It ensures continuous quality control without human intervention. This leads to faster and more accurate detection of issues.

Defect Detection

Defect detection is crucial in the steel industry. AI systems identify defects that human inspectors might miss. These systems use advanced algorithms to analyze visual data.

AI can detect surface defects, such as cracks or inclusions. It also identifies internal defects that affect the steel’s integrity. This ensures that only high-quality steel reaches the market.

AI systems improve the overall efficiency of the defect detection process. They reduce the time and cost associated with manual inspections. This leads to higher quality steel products and satisfied customers.

Optimizing Supply Chains

Artificial intelligence (AI) is transforming the steel industry by optimizing supply chains. It helps companies manage inventory, streamline logistics, and reduce operational costs. Let’s explore how AI enhances these processes.

Inventory Management

Effective inventory management is crucial in the steel industry. AI-powered systems provide real-time data, predicting demand and supply accurately. Companies can maintain optimal stock levels. This reduces storage costs and prevents stockouts.

AI algorithms analyze past sales data. They identify patterns and forecast future demand. This helps in planning production schedules and managing resources efficiently.

Logistics Optimization

AI plays a significant role in logistics optimization. It helps in selecting the best routes for transportation. This ensures timely delivery and reduces fuel costs.

AI systems track shipments in real-time. They predict potential delays and suggest alternative routes. This improves delivery efficiency and customer satisfaction.

| AI in Logistics | Benefits |

|---|---|

| Route Optimization | Reduces fuel costs |

| Real-time Tracking | Predicts delays |

| Alternative Routes | Ensures timely delivery |

In summary, AI enhances supply chain efficiency. It improves inventory management and optimizes logistics. This leads to cost savings and better customer service.

Credit: www.bcg.com

Energy Efficiency

Energy efficiency is a key focus in the steel industry. With the rise of artificial intelligence (AI), companies can now optimize their energy use. AI helps reduce energy waste and improve overall efficiency.

Energy Consumption Analysis

AI analyzes energy consumption in real-time. It collects data from various sources within the plant. This data helps identify areas with high energy use. By understanding these patterns, companies can make informed decisions.

AI systems can predict energy needs. This reduces unnecessary energy use. It also helps in planning energy consumption better. A well-planned energy use schedule saves money and resources.

Sustainable Practices

AI promotes sustainable practices in steel production. It helps monitor and control emissions. Reducing emissions is crucial for the environment. AI systems ensure that the production process is as eco-friendly as possible.

AI also supports the use of renewable energy. It can integrate renewable sources into the energy grid. This reduces reliance on non-renewable energy. Sustainable practices benefit both the industry and the planet.

Workplace Safety

Workplace safety in the steel industry is a top priority. AI technology helps ensure that safety standards are met. It reduces the risks and hazards that workers face daily. AI tools have the capability to detect dangers and automate risky tasks. This ensures a safer environment for everyone.

Hazard Detection

AI systems can identify potential hazards in the steel industry. They use sensors and cameras to monitor the workplace. These tools can detect issues like gas leaks, equipment malfunctions, and fire risks. Early detection allows for quick response, preventing accidents before they happen.

Employees can focus on their tasks without constantly worrying about hidden dangers. This increases productivity and peace of mind. AI-driven hazard detection is a critical component of workplace safety.

Automation Of Dangerous Tasks

AI can automate dangerous tasks in the steel industry. Robots can handle tasks that are too risky for humans. For example, AI-driven machines can manage the handling of molten steel. This reduces the risk of burns and other injuries.

Automating these tasks ensures that workers stay safe. They no longer need to perform high-risk activities. This leads to fewer accidents and a safer work environment. AI-driven automation is a crucial step in improving workplace safety in the steel industry.

Cost Reduction

Cost Reduction is crucial in the steel industry. By integrating AI, companies can save money and improve efficiency. AI helps in minimizing waste, optimizing resource allocation, and much more.

minimizing Waste

AI can help minimize waste in steel production. It achieves this by analyzing data in real-time and predicting issues before they happen. This reduces material waste and improves the quality of the steel produced.

For example, AI can detect defects early. It prevents defective steel from going through the entire production process. This saves both time and resources.

resource Allocation

AI optimizes resource allocation. It ensures that the right amount of materials and energy are used at each stage of production. This balance reduces costs and maximizes output.

An AI system can also forecast demand. This helps in planning production schedules efficiently. The steel industry can avoid overproduction and underproduction, both of which lead to losses.

Here’s how AI helps in resource allocation:

- Forecasting demand accurately

- Optimizing material usage

- Reducing energy consumption

- Improving labor productivity

All these factors contribute to significant cost reduction in the steel industry.

Data-driven Decisions

In the steel industry, data-driven decisions are becoming essential. Using AI and big data, companies can improve efficiency and productivity. These technologies help in making informed choices based on real-time data.

Big Data Integration

Big data integration is crucial for the steel industry. Data from various sources is collected and combined. This provides a comprehensive view of operations. AI tools process this data quickly. They identify patterns and trends that might go unnoticed.

Analytics And Insights

With the integration of big data, analytics and insights become accessible. AI algorithms analyze the data to provide valuable insights. These insights help in predicting maintenance needs. They also aid in optimizing production schedules.

By using these insights, steel companies can reduce downtime. They can also improve their overall efficiency. Data-driven decisions thus lead to better outcomes.

Future Trends

The steel industry is evolving with the integration of AI. These advancements promise to transform traditional practices. Let’s explore some of these future trends that are shaping the industry.

Ai And Iot

AI and IoT work together to improve steel production. Sensors collect real-time data from machines. AI analyzes this data to predict failures. This prevents downtime and reduces maintenance costs.

IoT devices monitor the entire production process. They ensure optimal conditions for steel making. AI helps in adjusting parameters for better output. This leads to higher quality steel with less waste.

Blockchain Integration

Blockchain technology is gaining traction in the steel industry. It offers a secure way to track steel products. Each step of the production and supply chain is recorded. This ensures transparency and traceability.

Blockchain helps in verifying the quality of raw materials. It also ensures compliance with industry standards. This builds trust with customers and stakeholders. Blockchain integration can streamline transactions and reduce fraud.

Frequently Asked Questions

What Is Ai In The Steel Industry?

AI in the steel industry involves using advanced algorithms to optimize production processes. It improves efficiency, quality, and reduces costs.

How Does Ai Enhance Steel Production?

AI enhances steel production by predicting equipment failures, optimizing energy use, and improving product quality. It leads to smarter manufacturing.

What Benefits Does Ai Bring To Steel Manufacturing?

AI brings numerous benefits including reduced downtime, lower operational costs, and improved product consistency. It also enhances decision-making.

Can Ai Predict Maintenance Needs In Steel Plants?

Yes, AI can predict maintenance needs by analyzing data from machinery. This helps in preventing unexpected breakdowns.

Conclusion

AI is transforming the steel industry. It improves efficiency and reduces costs. Predictive maintenance reduces downtime. Quality control ensures better products. Smart automation optimizes production. These advancements lead to a more sustainable industry. AI also enhances decision-making. It provides valuable insights and real-time data.

Embracing AI technology offers a competitive edge. The steel industry benefits greatly from AI’s innovations. Future prospects look promising with continued AI integration.