Robotics can transform bread and cake production. They offer precision and efficiency.

In today’s fast-paced world, the food industry constantly seeks ways to improve production. How robotics can be used in the manufacturing of breads and cakes? Robotics is one such advancement revolutionizing the manufacturing process of breads and cakes. By integrating robots, bakeries can achieve consistent quality, reduce human error, and speed up production.

This technology not only ensures the precise mixing and baking of ingredients but also enhances packaging efficiency. As a result, consumers enjoy fresher, better-quality products while businesses benefit from increased productivity. Dive in to discover how robotics can be used in the manufacturing of breads and cakes?

Introduction To Robotics In Baking

The baking industry constantly evolves. Traditional methods often fall short in meeting high demands. Robotics offers a new solution. This technology changes how breads and cakes are made. Efficiency increases, and quality improves. Robotics also helps maintain consistency in every batch.

Modern Baking Challenges

Baking faces many challenges. High demand is one of them. Traditional methods struggle to keep up. Human error also impacts quality. Consistency becomes difficult to achieve. Labor costs are another concern. Skilled bakers are hard to find. Training new staff takes time.

Emergence Of Robotics

Robotics addresses these issues. Robots work tirelessly. They ensure uniformity in every loaf and cake. Robots reduce labor costs. They also minimize human error. The baking process becomes more efficient. Robots can mix, knead, and bake with precision. Quality improves, and waste decreases.

Credit: www.processindustryforum.com

Types Of Robots In Baking

Robotics is transforming the baking industry. Different robots perform various tasks in bread and cake manufacturing. They streamline operations and ensure consistency. Let’s explore the main types of robots used in baking.

Mixing Robots

Mixing robots handle the blending of ingredients. They ensure precise measurements and thorough mixing. This results in consistent dough quality. Mixing robots save time and reduce human error. They can work with various recipes and ingredient combinations.

Kneading Robots

Kneading robots take the mixed dough and knead it to perfection. They replicate the traditional kneading process with precision. These robots ensure uniform texture and elasticity. Kneading robots can work continuously without tiring. This increases efficiency in large-scale production.

Shaping And Molding Robots

Shaping and molding robots give the dough its final form. They can create different shapes and sizes of bread and cakes. These robots are programmable for various designs. They ensure uniformity in each product, which is crucial for branding. Shaping and molding robots also speed up the production line, ensuring a consistent output.

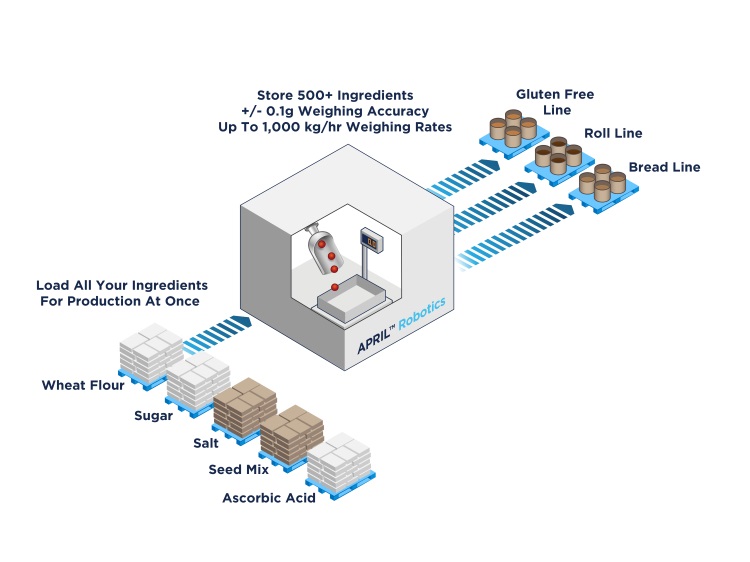

Automation In Ingredient Handling

Automation in ingredient handling is transforming the baking industry. Robots help in measuring, mixing, and preparing ingredients for bread and cakes. This technology ensures accuracy and consistency, improving the quality of baked goods. Let’s explore how automation can enhance ingredient handling.

Precision In Measurements

Robots can measure ingredients with high precision. This ensures each batch has the same taste and texture. Precise measurements reduce waste and save costs. Robots use sensors to weigh ingredients accurately. They follow recipes exactly, which maintains product quality.

Efficiency In Mixing

Efficient mixing is crucial in baking. Robots can mix ingredients thoroughly and consistently. They ensure that dough and batter have a uniform texture. This results in better bread and cakes. Robots can mix large batches quickly. This increases production speed and reduces human effort.

Credit: stockcake.com

Enhancing Dough Preparation

In the world of baking, robotics is becoming a crucial tool. It offers remarkable efficiency in the preparation of dough. This technological advancement ensures the dough is consistently perfect for both breads and cakes. Let’s dive into how robots enhance dough preparation.

Consistent Kneading

Robots can knead dough with precise movements. This ensures the same level of consistency every time. Traditional kneading can vary. It depends on human strength and technique. A robot, however, uses programmed actions. These actions are always the same.

The result is predictable. The dough is always smooth and elastic. This consistent kneading process saves time. It reduces errors in the dough preparation stage.

Uniform Dough Quality

Uniformity in dough quality is crucial for baking. Robots ensure each batch of dough is the same. They measure and mix ingredients with precision. This removes the risk of human error.

With robotic assistance, the dough is well-mixed. It has the right texture and consistency. This uniform quality leads to better bread and cake products. The end result is reliable and delicious baked goods every time.

| Traditional Kneading | Robotic Kneading |

|---|---|

| Varies with human effort | Consistent with programmed actions |

| Time-consuming | Time-efficient |

| Prone to errors | Error-free |

Incorporating robots in dough preparation enhances efficiency. It also ensures consistent quality. This innovative approach is transforming the baking industry.

Shaping And Molding Innovations

Robotics is transforming the manufacturing of breads and cakes through innovative shaping and molding techniques. These advancements ensure precise and unique designs, enhancing both the visual appeal and quality of baked goods.

Custom Shapes And Designs

Robots can create custom shapes and designs with ease. This allows bakeries to offer a variety of unique products. From heart-shaped cakes to intricately designed breads, the possibilities are endless. Robots use advanced programming to shape dough precisely. This ensures each piece is consistent and attractive. Custom molds and cutters can be programmed for specific designs. This reduces manual labor and increases production speed. Customers love the variety and creativity this brings to their baked goods.

Consistency In Size

Consistency in size is crucial in the baking industry. Robots excel at this task, producing uniform loaves and cakes every time. They measure and divide dough accurately. This ensures each piece is the same size and weight. Consistent sizing improves the baking process. It ensures even cooking and a better end product. Uniform products are more appealing to consumers. They also help bakeries maintain their brand reputation. Using robots for shaping and molding enhances efficiency and consistency in the baking process.

Robotics In Baking And Cooking

The use of robotics in baking and cooking has transformed the way we produce breads and cakes. Robotics technology ensures consistency, quality, and efficiency in the baking process. Automated systems help bakers achieve precise measurements and control baking conditions. This results in perfect products every time.

Precision Baking

Robots measure ingredients with high accuracy. They follow recipes precisely. This reduces human error. Consistent measurements lead to better quality breads and cakes. Robots can also shape dough uniformly. This ensures each loaf or cake looks the same.

Temperature Control

Temperature control is crucial in baking. Robots monitor and adjust oven temperatures. They ensure the dough is baked at the right temperature. This prevents undercooking or burning. It also helps maintain the texture and taste of the products.

Packaging And Quality Control

The use of robotics in the manufacturing of breads and cakes is revolutionizing the industry. One key area where robots excel is in packaging and quality control. This ensures that products are packaged efficiently and meet the highest standards of quality.

Automated Packaging

Automated packaging systems help in streamlining the packing process. Robots can swiftly place breads and cakes into packaging, reducing human error. Here are some benefits of automated packaging:

- Increases speed and efficiency

- Reduces labor costs

- Minimizes contamination risks

These systems can handle delicate items carefully. They also ensure that each product is consistently packaged, maintaining brand quality.

Inspection And Quality Assurance

Inspection and quality assurance are crucial in the food industry. Robots equipped with advanced sensors can detect defects in breads and cakes. These robots ensure that only products meeting high standards reach the consumers. The benefits of robotic inspection include:

- Accurate defect detection

- Consistent quality control

- Increased production efficiency

Robots can inspect every product faster than humans. They can identify imperfections such as shape, size, and texture inconsistencies. This ensures that consumers always get the best quality products.

Integrating robotics into bread and cake manufacturing enhances both packaging efficiency and quality control. This leads to better productivity and superior products for consumers.

Future Of Robotics In Baking

Robots can mix ingredients, knead dough, and bake breads and cakes with precision. Automation helps maintain consistency and improves efficiency in baking. This technology reduces labor costs and enhances product quality.

The future of robotics in baking is exciting. Many bakeries now use robots to help make bread and cakes. Robots can work faster and more precisely than people. This helps to make sure that every product is of high quality. As technology improves, robots will become even better at baking.

Advancements In Technology

Robots are getting smarter. New sensors and software help robots to see and feel. This means they can handle delicate tasks, like decorating cakes. 3D printing is another big step. With it, robots can create intricate designs on cakes. This allows for more creative freedom in baking.

Machine learning also helps. Robots can learn from past mistakes. They get better with each batch of bread or cake. This leads to consistent quality in every product. Automation tools also help in mixing and kneading dough. This saves time and ensures the dough is just right.

Potential Challenges

There are some challenges with using robots in baking. One big issue is cost. High-quality robots can be expensive. Not all bakeries can afford them. Another challenge is maintenance. Robots need regular upkeep to work well. This can be time-consuming and costly.

Training staff to use robots is also important. Workers need to learn new skills. This can take time and effort. Some people worry about job loss. Robots might replace some human workers. But they can also create new jobs in tech and maintenance.

The future of robotics in baking looks bright. But it also comes with challenges. With the right approach, bakeries can benefit greatly.

“`

Credit: soft-gripping.com

Frequently Asked Questions

how robotics can be used in the manufacturing of breads and cakes?

Robots automate repetitive tasks like mixing, kneading, and shaping dough. They ensure consistency and efficiency in the baking process.

What Benefits Do Robots Bring To Bread Manufacturing?

Robots increase production speed, improve product quality, and reduce human error. They also minimize labor costs and enhance workplace safety.

Can Robots Decorate Cakes?

Yes, robots can precisely decorate cakes. They can apply icing, create intricate designs, and ensure uniformity, enhancing the presentation.

Are Robotics Cost-effective In Bakery Production?

Yes, investing in robotics can be cost-effective. They reduce labor costs and production downtime, leading to long-term savings.

Conclusion

Robotics in bread and cake manufacturing brings efficiency and consistency. Robots handle repetitive tasks quickly. This reduces human error and labor costs. Improved quality control ensures each product meets standards. How robotics can be used in the manufacturing of breads and cakes? Automation helps meet high demand with ease. Technology in baking offers many benefits.

Embrace robotics for better productivity and quality. Enjoy fresher, tastier baked goods made with precision. The future of baking looks bright with robotics.